Fine Boring Machines

Fine Boring Machines

High efficiency: Compared with manual operation and other machining methods, Fine Boring Machines machining has the advantage of high efficiency and can complete machining tasks quickly. Its cutting speed is very high, usually between 500~1000m/min, and the cutting depth and feed rate are very small, the cutting depth is generally 0.05~0.2mm, and the feed rate is generally 0.02~0.08mm/r.

Wide applicability: Because the shape of the boring machine tool can be designed according to needs, it is very suitable for processing various irregular shape workpieces, such as internal holes, threaded holes, etc. In addition, the use of different tools and accessories can also be drilling, milling and other processing, processing accuracy and surface quality is higher than the drilling machine.

Product description

The working principle of Fine Boring Machines is that the rotation of the boring tool is the main movement, and the movement of the boring tool or the workpiece is the feed movement, which is used for machining high-precision holes or completing the finishing of multiple holes at one time. The boring of long holes represented by the axial hole system of box parts is one of the most important contents in metal cutting.

Although there are still examples of long hole Boring using boring die, guide sleeve, table milling and boring machine behind the column supporting the long boring bar or manually finding the workpiece turning 180°, in recent years, on the one hand, due to the extensive use of Fine Boring Machines and machining centers, The coordinate positioning accuracy and rotary indexing accuracy of all kinds of Fine Boring Machines have been greatly improved.

On the other hand, the mass production and application of ordinary or Fine Boring Machines in the shape of the bed layout, the turn boring of the table 180° self-positioning from the machine structure, Almost the method for Boring long holes in such Fine Boring Machines.

Product Pictures

Product characteristics

Fine Boring Machines, also known as diamond boring machines, are machines that use tools such as diamond, cubic boron nitride, or cemented carbide to perform precision boring. Its characteristics mainly include the following aspects:

High precision: Fine Boring Machines is a high-precision machining method that can generally reach an accuracy of less than 0.01mm. In the mass production of automobiles, tractors, internal combustion engines and other manufacturing industries, it is widely used in the semi-finishing and finishing of high-precision holes, aperture accuracy IT6, hole shape error between 2~5μm, surface roughness Ra1.6~0.2μm.

Good stability: Fine Boring Machines are usually designed with a high rigid structure to ensure machine stability and accuracy during high-speed cutting processes.

High degree of automation: Modern Fine Boring Machines are usually equipped with CNC systems, which can realize coordinate positioning and machining process automation, improving production efficiency and machining accuracy.

In general, Fine Boring Machines play an important role in the field of mechanical manufacturing with their high precision, high efficiency, wide applicability, good stability and high degree of automation.

About Company

Dezhou XinHongJi CNC Machinery Co., Ltd. Mainly engaged in Skiving Roller Burnishing,Hole Boring Machine,Honing Machine manufacturing.

We assure you that we will continue to serve our customers.

Engineering case

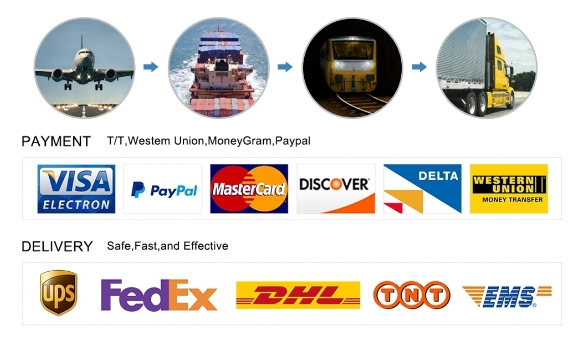

Payment and Transport